History

Stages of the Company's Development

2004

Opened a representative office in Cherepovets.

Started hosting annual international conferences aimed at addressing the challenges of accident-free operations in industries with power drives.

Launched mass production of refueling units for hydraulic stations.

Started hosting annual international conferences aimed at addressing the challenges of accident-free operations in industries with power drives.

Launched mass production of refueling units for hydraulic stations.

2003

Commissioned an office center with a total area of 900 sq. m.

Started work on the modernization of electro-hydraulic systems for automatic regulation of hydraulic turbines based on in-house produced servo valves.

Started work on the modernization of electro-hydraulic systems for automatic regulation of hydraulic turbines based on in-house produced servo valves.

2002

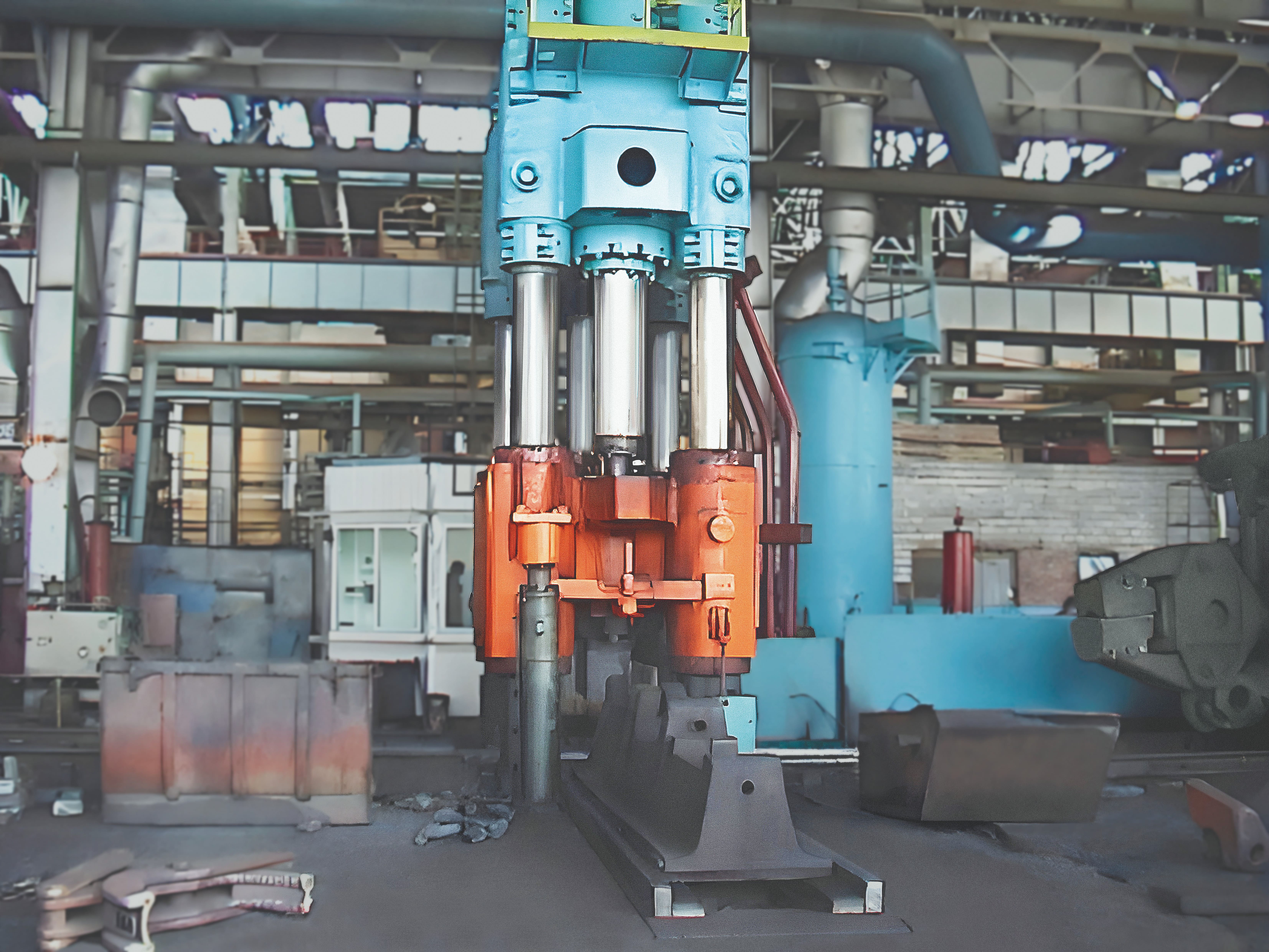

The first major project in non-ferrous metallurgy - modernization of the control system and electro-hydraulic drives of the R800 radial forging machine by SACK for OAO "Corporation VSMPO-AVISMA"

Commissioned the first own building – the Scientific and Production Center, with a total area of 1240 sq. m.

Established a Training Center based at the South Ural State University.

Commissioned the first own building – the Scientific and Production Center, with a total area of 1240 sq. m.

Established a Training Center based at the South Ural State University.

2001

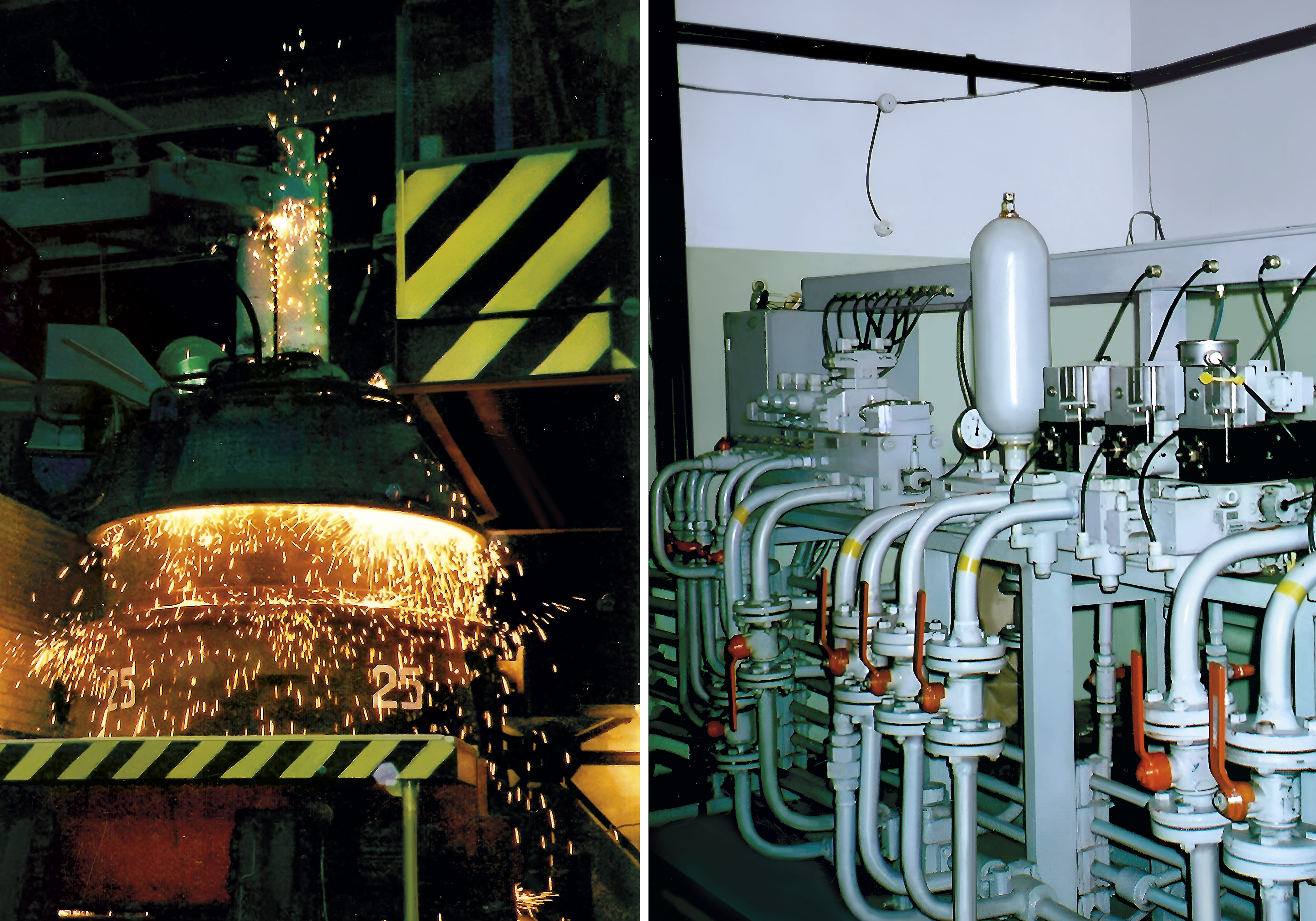

The first subcontract work with the leading foreign company VAIS: modernization of the arc steelmaking furnace DSP-25 and the forging complex (2000-ton press and two 10-ton manipulators) at OAO "BUMMASH", Izhevsk.

1999

A model range of servo and proportional valves of the original design by UrIC was developed and launched into production.

A control system for the complex steel processing unit (AKOS) with a capacity of 130 tons with automatic arc regulators was completed.

A control system for the complex steel processing unit (AKOS) with a capacity of 130 tons with automatic arc regulators was completed.

1998

Mass production of filters, reusable filter elements, and ultrasonic stations for cleaning filter elements has been organized.

1997

The first major project in the field of ferrous metallurgy – modernization of the anti-bending system on the 2000 hot rolling mill at OJSC "MMK" with the successful use of servo valves of our own original design.

1995

The first company, "Training and Engineering Center," was established with a total of 3 employees from the Department of Hydraulic Drive at South Ural State University.